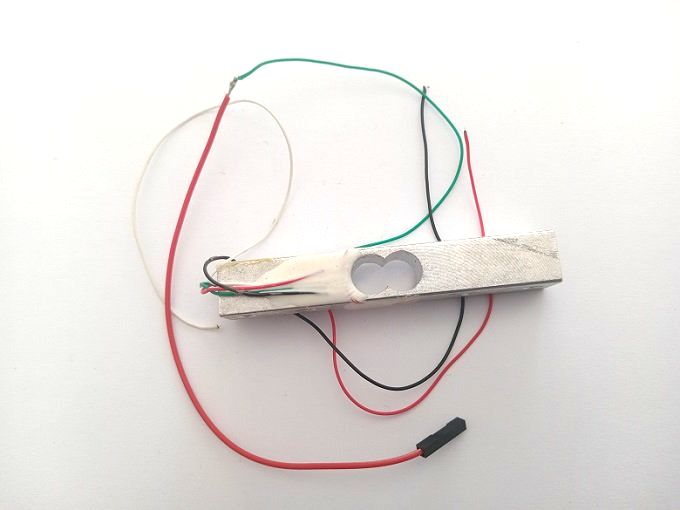

The weight sensor

What is the weight sensor ?

A weight sensor is a type of sensor that is used to measure the weight or force applied to a surface. Weight sensors are commonly used in a variety of applications, such as industrial and manufacturing processes, healthcare, automotive, and consumer products. They are also commonly used in robotics and automation projects.

There are several types of weight sensors, including load cells, strain gauges, piezoelectric sensors, and capacitive sensors. Load cells are the most common type of weight sensor and are used in a wide range of applications. They are typically made of a metal structure that is designed to deform when a force is applied to it, and the deformation is measured using a strain gauge or other type of sensor.

Weight sensors can be used to measure both static and dynamic forces, and they can be calibrated to provide accurate measurements over a wide range of weights. In addition, many weight sensors are equipped with digital interfaces that allow them to be connected to a microcontroller or other device for data collection and analysis.

Overall, weight sensors are an important component in many applications where accurate and precise weight measurements are necessary, and they play a crucial role in robotics and automation projects where the ability to detect and respond to changes in weight is critical for the performance of the system.

Weight sensor and microcontrollers

Microcontrollers are commonly used to interface with weight sensors and process the data that they provide. The microcontroller can read the weight sensor data using an analog or digital interface, depending on the type of sensor used. The microcontroller can then process the data and use it to control other components in the system or send the data to a computer or other device for further analysis.

One common use of weight sensors and microcontrollers is in industrial automation applications. For example, a weight sensor may be used to measure the weight of a product on a conveyor belt, and the microcontroller can use this data to control the speed of the belt or divert the product to a different conveyor based on its weight.

In robotics applications, weight sensors can be used to detect changes in weight and adjust the robot's movements or behavior accordingly. For example, a robot carrying a load may use a weight sensor to detect when the load is getting too heavy and adjust its movements to compensate.

Microcontrollers can also be used to calibrate and configure weight sensors to ensure accurate and reliable measurements. For example, a microcontroller may be used to adjust the sensitivity or offset of a load cell or to compensate for temperature variations that may affect the accuracy of the weight sensor.

How to use the weight sensor by the Arduino board ?

To use a weight sensor with an Arduino board, you will need a compatible weight sensor module and a breadboard and jumper wires. Here are the steps to follow:

1- Connect the weight sensor module to the breadboard and connect the VCC and GND pins of the module to the 5V and GND pins of the Arduino board, respectively.

2- Connect the output pin of the weight sensor module to an analog input pin of the Arduino board (e.g. A0).

3- Write the Arduino code to read the sensor data. Here's an example code that reads the weight sensor data and prints it to the Serial Monitor:

|

1 2 3 4 5 6 7 8 9 10 11 12 13 |

const int weightSensorPin = A0; // analog input pin for weight sensor int sensorValue = 0; // variable to store sensor data void setup() { Serial.begin(9600); // initialize serial communication } void loop() { sensorValue = analogRead(weightSensorPin); // read the sensor data Serial.print("Sensor Value: "); Serial.println(sensorValue); // print the sensor value to the serial monitor delay(1000); // wait for a second before taking the next reading } |

4- Upload the code to the Arduino board and open the Serial Monitor in the Arduino IDE. You should see the sensor data being printed to the Serial Monitor in real-time.

Note: The exact code and wiring may vary depending on the specific weight sensor module you are using. Be sure to consult the datasheet or instructions for your weight sensor module for more specific guidance.

Role of the weight sensor in robotic projects

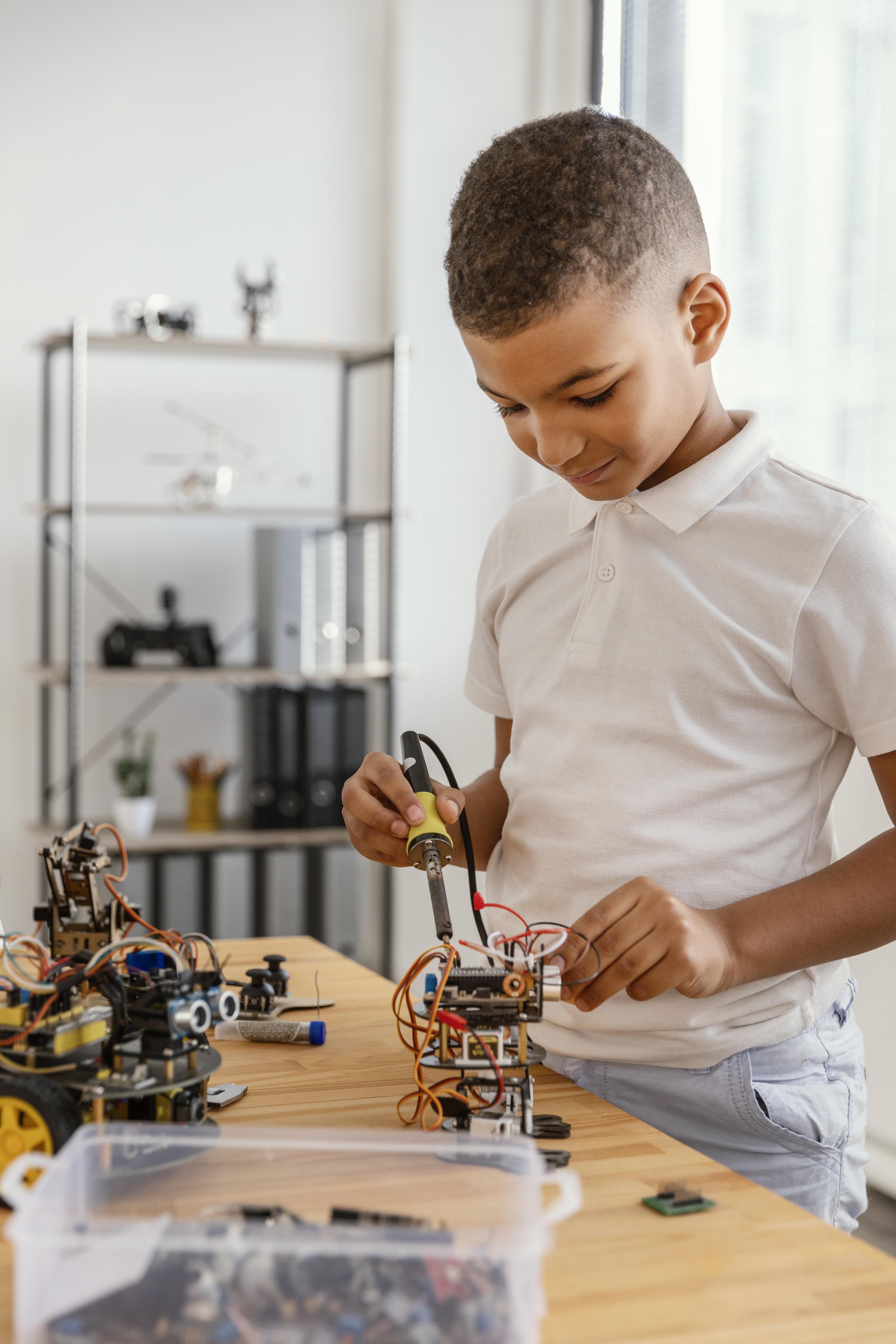

Weight sensors can play a significant role in robotic projects. They can be used to provide feedback on the weight or mass of an object, which can be used to control the movements or behavior of the robot.

Here are a few examples of how weight sensors can be used in robotic projects:

Load-bearing robots: Weight sensors can be used to detect the weight of a load that a robot is carrying. The robot can use this information to adjust its movements, such as slowing down or stopping if the load is too heavy. This can help ensure the safety of the robot and prevent damage to the load.

Humanoid robots: Weight sensors can be used to detect changes in the robot's weight distribution, which can be used to adjust its balance and prevent it from falling over. This can be particularly important in humanoid robots, which are designed to mimic human movements and require precise balance and coordination.

Sorting robots: Weight sensors can be used to sort objects based on their weight. For example, a sorting robot could use weight sensors to sort objects into light and heavy categories, which could be used to separate recyclable materials from non-recyclable materials.

Agricultural robots: Weight sensors can be used to measure the weight of crops, such as fruit or vegetables. This can be used to monitor crop yields and optimize harvesting processes.