The servo motor

Definition of servo motor

A servo motor is an electro-mechanical device that uses feedback control to accurately and precisely control the movement of a shaft or output. It consists of a DC motor, a gearbox, a control circuit, and a potentiometer or an encoder for feedback. Servo motors are commonly used in various industrial applications, robotics, and hobbyist projects.

The control circuit of a servo motor receives an input signal, usually in the form of a pulse-width modulation (PWM) signal, which determines the desired position of the output shaft. The control circuit then compares the desired position to the actual position, which is determined by the feedback device, and adjusts the speed and direction of the motor to move the output shaft to the desired position. This closed-loop control system allows servo motors to provide accurate and precise control of movement.

Servo motors are available in various types and sizes, with different torque, speed, and accuracy specifications. They can rotate over a limited range of angles, typically from 0 to 180 degrees, or in some cases, provide continuous rotation. Servo motors are widely used in robotics, automation, CNC machines, cameras, remote-controlled vehicles, and other applications that require precise and controlled movement.

Types of servo motors

There are several types of servo motors, each with its own characteristics and applications. Here are some of the most common types:

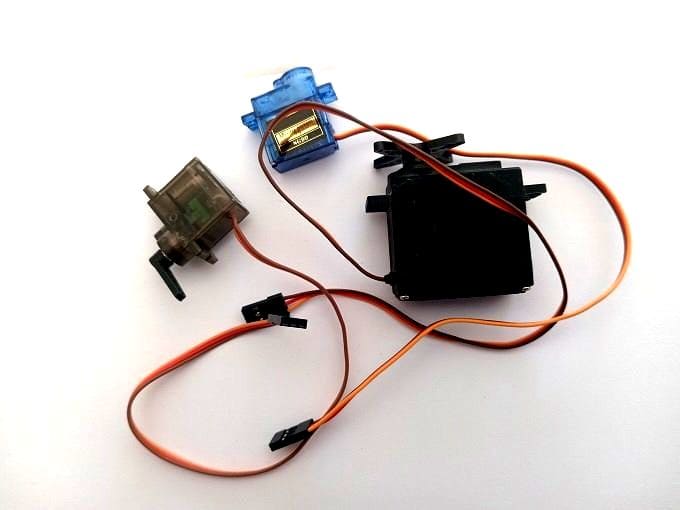

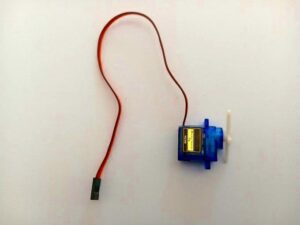

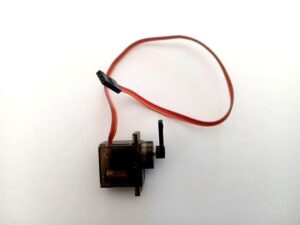

MINI SERVO MOTOR SG-90 SG90

The SG90, also known as the Mini Servo Motor SG90, is a popular and inexpensive micro-sized servo motor commonly used in hobbyist projects, such as remote-controlled vehicles, model airplanes, and robotics. It is a DC motor-based servo that operates on a voltage range of 4.8V to 6V, and is capable of providing up to 2.5 kg-cm of torque.The SG90 has a 180-degree range of motion and can be controlled using PWM signals. It is a lightweight and compact servo motor, with a weight of only 9 grams and dimensions of 23mm x 12.2mm x 29mm. Despite its small size, the SG90 is capable of delivering precise and stable movement, making it a popular choice for small-scale projects.

However, it should be noted that the SG90 may not be suitable for high-precision applications that require higher torque, speed, and accuracy. It is more suited for hobbyist projects and simple robotic applications where cost and size are important factors.

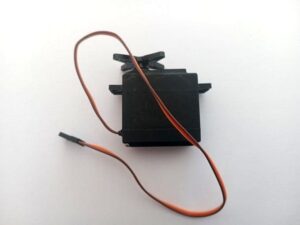

PRO SERVO 996R MG996 360°

The MG996R is a high-torque and high-performance servo motor that is capable of providing up to 11kg-cm of torque at 6V. It is commonly referred to as the "Pro Servo 996R" or simply "MG996", and is widely used in robotics, RC vehicles, and other industrial applications.The MG996R is a digital servo motor that operates on a voltage range of 4.8V to 7.2V, and is capable of rotating continuously over 360 degrees, making it suitable for some applications where continuous rotation is required. It also features metal gears, which provide increased durability and resistance to wear and tear.

The control signal of the MG996R is a PWM signal with a frequency range of 50Hz to 333Hz, and a duty cycle range of 5% to 10%. It has a response time of 0.16 seconds/60 degrees at 4.8V and 0.13 seconds/60 degrees at 6V, which makes it a fast and responsive servo motor.

Overall, the MG996R is a reliable and powerful servo motor that is suitable for a wide range of applications that require high torque and precision. However, due to its relatively high cost and weight, it may not be suitable for some small-scale hobbyist projects.

Metal Servo MG90S

The MG90S is a high-performance servo motor that is commonly known as the "Metal Servo MG90S" or simply "MG90S". It is a digital servo motor that operates on a voltage range of 4.8V to 6.0V and is capable of providing up to 2kg-cm of torque.

The MG90S is known for its metal gears, which provide increased durability and resistance to wear and tear compared to plastic gears found in some other servo motors. It also features a 180-degree range of motion and can be controlled using PWM signals.

The response time of the MG90S is relatively fast, with a speed of 0.11 seconds/60 degrees at 4.8V and 0.10 seconds/60 degrees at 6V. This makes it suitable for applications that require quick and precise movement, such as robotics and RC vehicles.

One thing to note is that the MG90S has a relatively small size, with dimensions of 23mm x 12.2mm x 29mm and a weight of only 13.4 grams. This makes it a popular choice for small-scale hobbyist projects where space and weight are important factors.

Overall, the MG90S is a reliable and durable servo motor that is suitable for a wide range of applications, particularly those that require high precision and quick response times. Its metal gears and small size make it a popular choice for hobbyists and robotics enthusiasts.

How to operate the servo motor?

To operate a servo motor, you typically need to provide it with a control signal that contains information about the desired position or angle of rotation. This is done using a microcontroller or other electronic device capable of generating the necessary signal.

The most common way to control a servo motor is to use a Pulse-Width Modulation (PWM) signal. The PWM signal consists of a series of pulses with varying width, where the width of each pulse corresponds to a specific position or angle of rotation. For example, a pulse with a width of 1ms might correspond to a position of 0 degrees, while a pulse with a width of 2ms might correspond to a position of 180 degrees.

To generate a PWM signal, you need to determine the appropriate frequency and duty cycle for your servo motor. The frequency should typically be between 50Hz and 300Hz, while the duty cycle should be between 5% and 10%. You can adjust the duty cycle to change the position or angle of rotation of the servo motor.

Once you have generated the PWM signal, you need to send it to the servo motor using a signal wire. The servo motor will then use the information in the signal to adjust its position or angle of rotation accordingly.

How to control the servomotor by the microcontroller ?

To control a servo motor with a microcontroller, you typically need to follow these steps:

1- Connect the servo motor to the microcontroller: The servo motor should have three wires, usually colored red, black, and yellow or white. The red wire should be connected to a power source, usually 5V or 6V, while the black wire should be connected to ground. The yellow or white wire should be connected to a digital pin on the microcontroller that is capable of generating a PWM signal.

2- Initialize the PWM signal: In the setup() function of your microcontroller code, you should initialize a PWM signal on the digital pin connected to the servo motor. The exact code for this will depend on the microcontroller you are using, but it typically involves setting the pin mode to OUTPUT and configuring the frequency and duty cycle of the PWM signal.

3- Set the position of the servo motor: In the loop() function of your code, you can set the position of the servo motor by adjusting the duty cycle of the PWM signal. To do this, you can use the analogWrite() function in Arduino or a similar function in other microcontroller platforms. The exact values you need to use will depend on the specifications of your servo motor, so you may need to experiment with different values to achieve the desired position.

4- Repeat as necessary: You can repeat step 3 as necessary to continuously adjust the position of the servo motor. You can also add additional code to control the servo motor based on input from sensors or other devices connected to the microcontroller.

Why do we use the servo motor ?

Servo motors are used in many applications where precise position or angle control of a mechanism is required. They are often used in motion control systems for robots, drones, remote control planes and cars, 3D printers, and CNC machines.

The main advantage of servo motors is their ability to provide precise position control. Using a feedback loop, the servo motor can adjust its position in real-time to follow a command signal with high accuracy. Servo motors are also very efficient in terms of energy consumption, as they only use energy when the position needs to be adjusted.

Due to their precision and energy efficiency, servo motors are widely used in the fields of robotics, automation, and motion control.

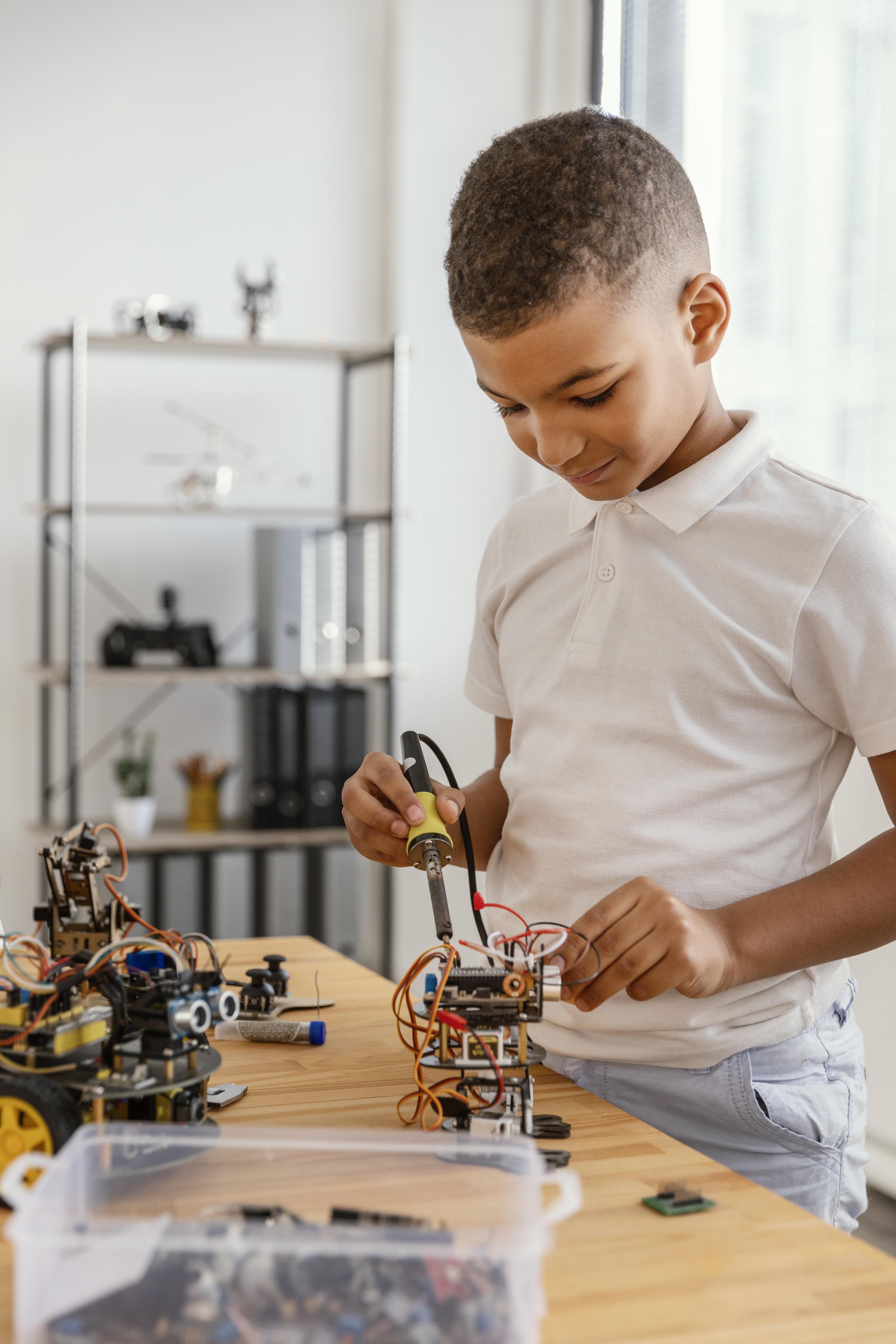

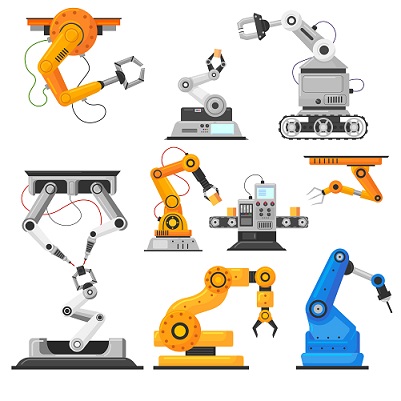

The servomotor and robotics

Servo motors play a crucial role in robotics as they provide precise control over the movement of robotic systems. In robotics, servo motors are often used to control the position and movement of robotic arms, grippers, and other end-effectors. By controlling the servo motor, a robot can achieve precise movements and positions required for various tasks such as assembly, manipulation, and pick-and-place operations.

Servo motors are also used in mobile robots to control their movement and steering. In such cases, servo motors are used in conjunction with wheels or other locomotion mechanisms to provide precise control over the speed and direction of the robot's movement.

In addition to their precise control capabilities, servo motors are also highly reliable and efficient, making them an ideal choice for use in robotics. They can operate for long periods without requiring maintenance or repairs, and can provide the high torque necessary for many robotic applications.