The DHT11 sensor

DHT11 Sensor Definition

The DHT11 sensor is a digital temperature and humidity sensor that is commonly used in electronic projects and devices. It is a low-cost sensor that is easy to use and can measure temperature and humidity with reasonable accuracy.

The DHT11 sensor works by measuring the resistance changes of a humidity-sensitive capacitor and a thermistor, which are located within the sensor's package. The resistance changes are then converted into digital signals, which are sent to a microcontroller for further processing.

The DHT11 sensor has a measurement range of 0-50°C for temperature and 20-90% for relative humidity, with an accuracy of ±2°C for temperature and ±5% for humidity. The sensor is powered by 3-5V DC and communicates with a microcontroller using a single-wire serial interface.

The DHT11 sensor is widely used in various applications such as environmental monitoring, indoor climate control, and weather stations. It is also commonly used in DIY projects, such as home automation systems, automatic plant watering systems, and smart thermostats.

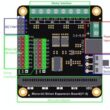

Composition of the DTH11 sensor

The DHT11 sensor is a digital temperature and humidity sensor that is composed of three main parts:

Humidity sensor: This part of the sensor consists of a humidity-sensitive capacitor that measures the relative humidity of the surrounding air. The capacitor is made of a polymer material that changes its capacitance as the humidity of the air changes.

Temperature sensor: The temperature sensor is a thermistor that measures the temperature of the surrounding environment. The thermistor is made of a material that changes its resistance as the temperature changes.

Signal processing and communication circuitry: This part of the sensor is responsible for processing the analog signals from the humidity and temperature sensors and converting them into digital signals. The circuitry also includes a microcontroller that controls the sensor's operations and communicates with external devices.

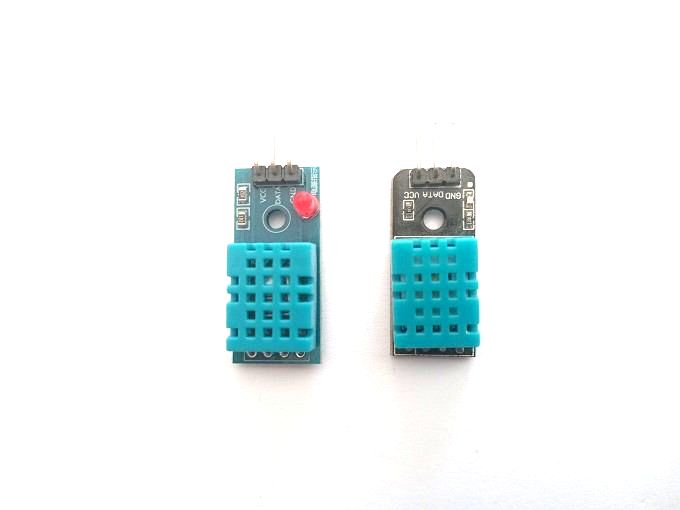

The DHT11 sensor is available as a pre-assembled module that includes the sensor itself and the signal processing circuitry. The module also has a protective casing to prevent damage to the sensor and to reduce electromagnetic interference with other electronic components.

DHT11 sensor pins

The DHT11 sensor has four pins, which are labeled on the module as VCC, GND, DATA, and NC. Here's a brief description of each pin:

VCC: This pin is used to power the DHT11 sensor. It should be connected to a 3-5V power source.

GND: This pin is the ground connection for the DHT11 sensor. It should be connected to the ground of the power source.

DATA: This pin is used to transmit data from the DHT11 sensor to a microcontroller or other device. The data is transmitted using a single-wire serial interface.

Programming the DHT11 sensor

Programming the DHT11 sensor involves reading the data from the sensor using a microcontroller or other device and interpreting the data to obtain the temperature and humidity readings. Here's a general overview of the steps involved:

1- Initialize the DHT11 sensor by setting the data pin as an output and sending a low signal to the pin for at least 18 milliseconds.

2- Switch the data pin to an input and wait for the DHT11 sensor to respond by pulling the data line low for 80 microseconds, followed by pulling it high for 80 microseconds.

3- Read the data from the DHT11 sensor by measuring the duration of the low and high pulses on the data line. The first 8 bits of data represent the integer part of the relative humidity, the next 8 bits represent the decimal part of the relative humidity, the next 8 bits represent the integer part of the temperature, and the final 8 bits represent the decimal part of the temperature.

4- Check the checksum to verify that the data received from the DHT11 sensor is valid. The checksum is calculated as the sum of the first 4 bytes of data and should match the last byte of data.

5- Convert the temperature and humidity data from the DHT11 sensor into the appropriate units and display or store the data as needed.

It's important to note that the timing requirements for reading data from the DHT11 sensor can be critical, and variations in timing can lead to errors or incorrect readings. Therefore, it's recommended to use a pre-existing library or code snippet for reading data from the DHT11 sensor rather than attempting to implement the protocol from scratch. Most microcontroller platforms, such as Arduino or Raspberry Pi, have pre-existing libraries or modules available for interfacing with the DHT11 sensor.

Role of the DHT11 sensor in industrial systems

The DHT11 sensor is commonly used in industrial systems to monitor temperature and humidity levels in various environments. Here are some examples of the role of the DHT11 sensor in industrial systems:

Environmental monitoring: The DHT11 sensor can be used to monitor the temperature and humidity levels in factories, warehouses, and other industrial environments. This data can be used to ensure that the environment is within acceptable ranges for the equipment being used or the products being produced.

HVAC control: The DHT11 sensor can be used to control heating, ventilation, and air conditioning (HVAC) systems in industrial buildings. The temperature and humidity data from the sensor can be used to adjust the HVAC system to maintain a comfortable and safe environment for workers.

Food storage and transportation: The DHT11 sensor can be used to monitor the temperature and humidity levels in food storage areas and during food transportation. This data can be used to ensure that the food is stored and transported at safe temperatures and humidity levels to prevent spoilage.

Agriculture: The DHT11 sensor can be used in agriculture to monitor the temperature and humidity levels in greenhouses and other growing environments. This data can be used to optimize plant growth and prevent damage from extreme temperatures or humidity levels.