Detect gas leak with ESP32 board and MQ-4 sensor

Tutorial plan

Introduction

1- How the ESP32 board controls the MQ-4 gas sensor ?

2- Gas detection system components

3- Mounting the ESP32 board with the MQ-4 sensor

4- Program the ESP32 board to detect the gas leak

Introduction

Gas leak detection refers to the process of identifying and locating leaks in systems that contain gases, such as natural gas, propane, methane, or other potentially hazardous gases. This process is crucial for ensuring safety, preventing accidents, and minimizing environmental impact.

Various methods and technologies are used for gas leak detection, including:

Gas Sensors: Gas sensors, such as the MQ-4 sensor mentioned earlier, are commonly employed for detecting specific gases. These sensors operate based on principles such as conductivity changes, catalytic reactions, or infrared absorption. They can be integrated into fixed systems or portable devices for continuous monitoring or spot-checking.

Electronic Gas Detectors: Electronic gas detectors are sophisticated instruments designed for detecting a wide range of gases. They typically utilize advanced sensor technologies combined with microcontrollers for accurate and reliable gas detection. These detectors may provide visual and audible alarms when gas concentrations exceed predefined thresholds.

Ultrasonic Leak Detectors: Ultrasonic leak detectors are capable of detecting gas leaks by sensing the ultrasonic sound produced by escaping gas. They are particularly useful for detecting leaks in pressurized systems or pipelines.

Flame Ionization Detectors (FID): FID instruments detect hydrocarbon gases by measuring the ionization of molecules in a flame. They are highly sensitive and are often used in industrial settings for detecting volatile organic compounds (VOCs) and other hydrocarbons.

Visual Inspection: Visual inspection involves physically inspecting gas pipes, fittings, valves, and other components for signs of leakage, such as corrosion, cracks, or damaged seals. This method is commonly used in conjunction with other detection techniques.

Gas Tracer Dyes: Gas tracer dyes are sometimes added to gas lines to aid in leak detection. These dyes are visible under ultraviolet light and can help locate leaks by fluorescing at the point of leakage.

Gas Chromatography: Gas chromatography is a laboratory technique used for analyzing the composition of gas samples. While not typically used for real-time leak detection, it can be employed for precise analysis and identification of gas components.

Effective gas leak detection often involves a combination of these methods to ensure comprehensive coverage and reliable results. Regular inspection, maintenance, and calibration of detection equipment are essential for maintaining the safety and integrity of gas systems.

How the ESP32 board controls the MQ-4 gas sensor ?

The ESP32 board can control the MQ-4 gas sensor through its GPIO (General Purpose Input/Output) pins. The MQ-4 gas sensor typically has four pins: VCC, GND, Analog Output, and Digital Output. Here's a general overview of how the ESP32 can control the MQ-4 gas sensor:

1- Power Supply: Connect the VCC pin of the MQ-4 sensor to a 5V power source. The ESP32 board usually operates at 3.3V, so make sure to regulate the voltage appropriately. Connect the GND pin of the MQ-4 sensor to the ground (GND) of the ESP32.

2- Analog Output: The MQ-4 sensor provides an analog output that varies depending on the concentration of the gas it detects. You can connect this analog output pin to one of the ADC (Analog to Digital Converter) pins of the ESP32. The ESP32 can then read this analog voltage and convert it to a digital value that represents the gas concentration.

3- Digital Output (optional): Some MQ series sensors also provide a digital output pin that gives a high or low signal based on a certain threshold of gas concentration. This pin can be connected to any digital GPIO pin on the ESP32. It allows for simple digital control and triggering based on gas presence.

4- Reading and Processing Data: With the analog output connected to an ADC pin, the ESP32 can periodically read the analog voltage using its ADC capabilities. This reading can then be processed to determine the concentration of the gas being detected. This processing can be done in the ESP32 firmware.

5- Data Transmission: Once the gas concentration is determined, the ESP32 can transmit this data to other devices or a central server using communication protocols such as Wi-Fi, Bluetooth, or MQTT. This allows for remote monitoring and analysis of gas levels.

6- Calibration and Calibration Feedback: It's important to calibrate the MQ-4 sensor periodically to ensure accurate readings. This calibration process can be initiated and managed by the ESP32 firmware. Additionally, feedback from the sensor can be used to determine if recalibration is necessary.

Gas detection system components

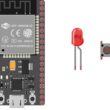

ESP32 Board:

The ESP32 is a powerful microcontroller developed by Espressif Systems. It's renowned for its integrated Wi-Fi and Bluetooth capabilities, making it a popular choice for various IoT (Internet of Things) applications.

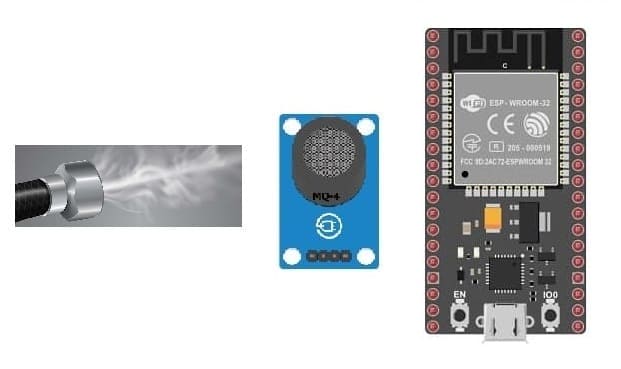

MQ-4 gas sensor:

The MQ-4 gas sensor is a type of semiconductor gas sensor commonly used to detect the presence of methane (CH4) gas in the atmosphere. It belongs to a family of gas sensors known as the "MQ series," which are widely used in various applications, including industrial safety, gas leakage detection, and environmental monitoring.

Jumper Wires:

For making temporary connections and wiring between components.

Breadboard:

A breadboard is a useful tool for creating temporary electronic circuits. It allows you to connect components without soldering.

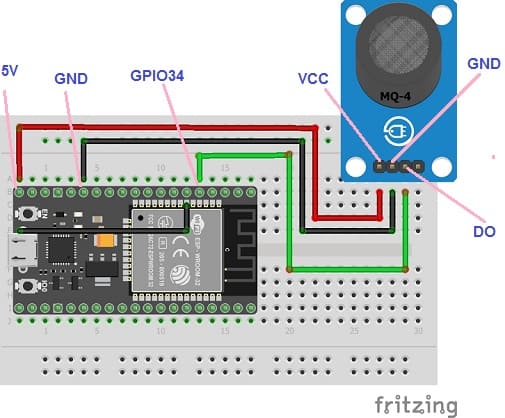

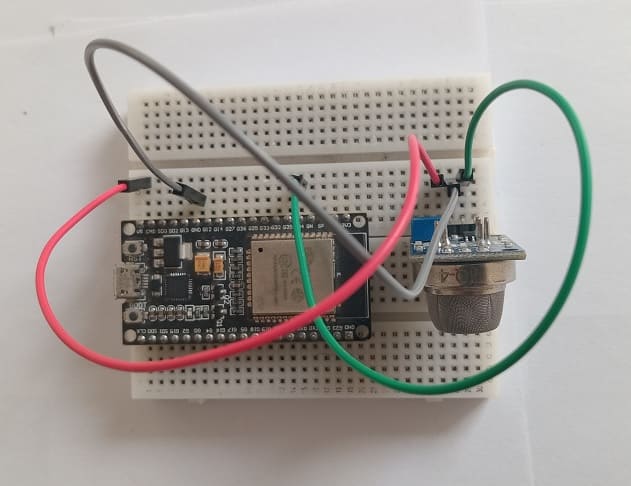

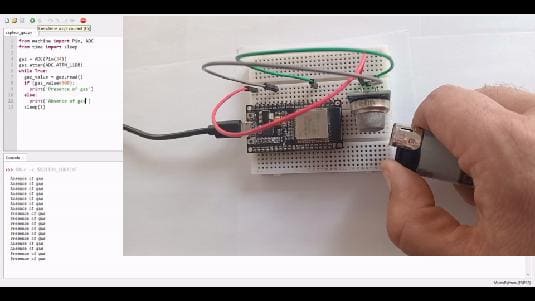

Mounting the ESP32 board with the MQ-4 sensor

Details of the MQ-4 sensor connections to the ESP32 board :

- Connect the VCC pin of the MQ-4 sensor to the 5V pin of the ESP32 board

- Connect the GND pin of the MQ-4 sensor to the GND pin of the ESP32 board

- Connect the DO pin of the MQ-4 sensor to the GPIO34 pin of the ESP32 board

Program the ESP32 board to detect the gas leak

To program the ESP32 board to detect gas leaks using MicroPython, you would need to utilize the ADC (Analog to Digital Converter) to read the analog output of the MQ-4 gas sensor and then set a threshold for detecting the presence of gas. Below is a simple example code to get you started:

|

1 2 3 4 5 6 7 8 9 10 11 12 |

from machine import Pin, ADC from time import sleep # Define ADC pin gaz = ADC(Pin(34)) <span class="hljs-comment"># Create ADC object</span> gaz.atten(ADC.ATTN_11DB) while True: gaz_value = gaz.read() if (gaz_value<500): # Example threshold, adjust as needed print('Presence of gas') else: print('Absence of gas') sleep(1) |

In this code:

1- We import the ADC module from the machine module, which allows us to use the ADC of the ESP32.

2- We define the pin to which the analog output of the MQ-4 sensor is connected (gaz). Adjust this pin according to your setup.

3- We create an ADC object (gaz) using the ADC pin.

4- The gaz.read() function reads the analog value from the ADC pin and maps it to a gas concentration value. You may need to calibrate this mapping based on your sensor's characteristics.

5- We set a threshold value (threshold=500) above which a gas leak is detected.

6- In the main loop, we continuously read the gas concentration using the gaz.read() function and print it.

7- If the gas concentration exceeds the threshold, we print a message indicating a gas leak has been detected. You can further extend this to take appropriate actions like sending alerts.

8- We then wait for a second before taking the next reading using sleep(1).

Remember to adjust pin numbers, threshold values, and calibration according to your specific setup and requirements. Additionally, ensure you have the necessary MicroPython firmware installed on your ESP32 board, and the board is properly connected to your development environment.