Detect gas leak with Arduino board and MQ-4 sensor

Tutorial plan

Introduction

1- What is the MQ-4 gas sensor ?

2- Gas detection system components

3- Mounting the Arduino board with the MQ-4 sensor

4- Program the Arduino board to detect the gas leak

Introduction

Gas leak detection refers to the process of identifying and locating leaks in systems that contain gases, such as natural gas, propane, methane, or other potentially hazardous gases. This process is crucial for ensuring safety, preventing accidents, and minimizing environmental impact.

Various methods and technologies are used for gas leak detection, including:

Gas Sensors: Gas sensors, such as the MQ-4 sensor mentioned earlier, are commonly employed for detecting specific gases. These sensors operate based on principles such as conductivity changes, catalytic reactions, or infrared absorption. They can be integrated into fixed systems or portable devices for continuous monitoring or spot-checking.

Electronic Gas Detectors: Electronic gas detectors are sophisticated instruments designed for detecting a wide range of gases. They typically utilize advanced sensor technologies combined with microcontrollers for accurate and reliable gas detection. These detectors may provide visual and audible alarms when gas concentrations exceed predefined thresholds.

Ultrasonic Leak Detectors: Ultrasonic leak detectors are capable of detecting gas leaks by sensing the ultrasonic sound produced by escaping gas. They are particularly useful for detecting leaks in pressurized systems or pipelines.

Flame Ionization Detectors (FID): FID instruments detect hydrocarbon gases by measuring the ionization of molecules in a flame. They are highly sensitive and are often used in industrial settings for detecting volatile organic compounds (VOCs) and other hydrocarbons.

Visual Inspection: Visual inspection involves physically inspecting gas pipes, fittings, valves, and other components for signs of leakage, such as corrosion, cracks, or damaged seals. This method is commonly used in conjunction with other detection techniques.

Gas Tracer Dyes: Gas tracer dyes are sometimes added to gas lines to aid in leak detection. These dyes are visible under ultraviolet light and can help locate leaks by fluorescing at the point of leakage.

Gas Chromatography: Gas chromatography is a laboratory technique used for analyzing the composition of gas samples. While not typically used for real-time leak detection, it can be employed for precise analysis and identification of gas components.

Effective gas leak detection often involves a combination of these methods to ensure comprehensive coverage and reliable results. Regular inspection, maintenance, and calibration of detection equipment are essential for maintaining the safety and integrity of gas systems.

What is the MQ-4 gas sensor ?

The MQ-4 gas sensor is a type of semiconductor gas sensor commonly used to detect the presence of methane (CH4) gas in the atmosphere. It belongs to a family of gas sensors known as the "MQ series," which are widely used in various applications, including industrial safety, gas leakage detection, and environmental monitoring.

The MQ-4 sensor operates on the principle of conductivity changes in its sensing material when exposed to the target gas. When methane molecules interact with the sensing material, they cause a change in the sensor's conductivity, which is then measured and converted into an electrical signal. This signal can be processed by a microcontroller or other electronic devices to trigger alarms, provide data logging, or control ventilation systems, depending on the application.

It's important to note that while the MQ-4 sensor is primarily designed for methane detection, it may also respond to other gases with similar properties, such as propane and butane. However, its sensitivity to these gases may vary, and it's typically calibrated specifically for methane detection.

Gas detection system components

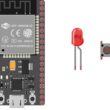

Arduino UNO Board

The Arduino Uno board is a microcontroller board based on the ATmega328P microcontroller. It's one of the most popular and widely used boards in the Arduino family due to its simplicity and versatility.

It is the central control unit for your project.

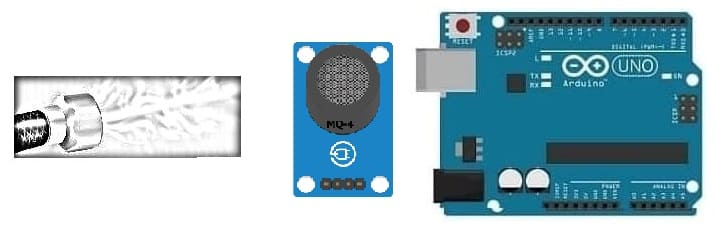

MQ-4 gas sensor:

The MQ-4 gas sensor is used to detect gas leak

Jumper Wires:

For making temporary connections and wiring between components.

Breadboard:

A breadboard is a useful tool for creating temporary electronic circuits. It allows you to connect components without soldering.

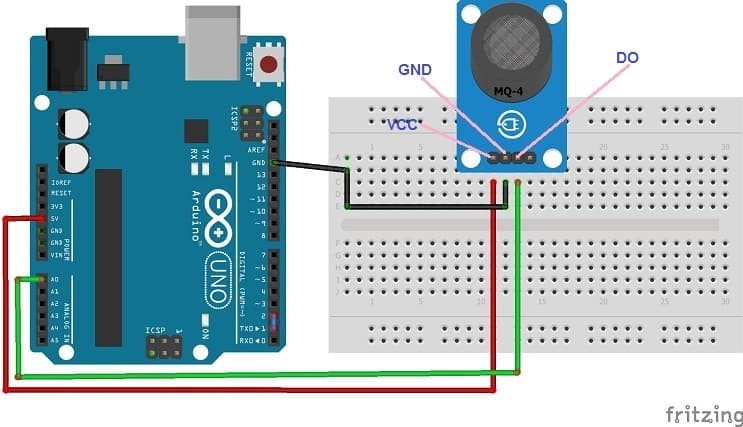

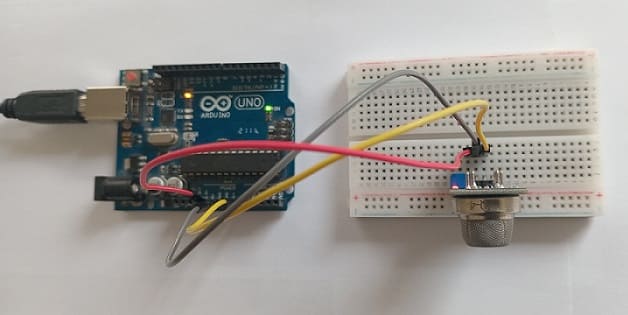

Mounting the Arduino board with the MQ-4 sensor

Details of the MQ-4 sensor connections to the Arduino board :

- Connect the VCC pin of the MQ-4 sensor to the 5V pin of the Arduino

- Connect the GND pin of the MQ-4 sensor to the GND pin of the Arduino

- Connect the DO pin of the MQ-4 sensor to the A0 pin of the Arduino

Program the Arduino board to detect the gas leak

Here's a basic example code to get you started. This code assumes you're using an analog pin to read the MQ-4 sensor :

|

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 |

#include <SoftwareSerial.h> int analogPin = A0; // Capteur de gaz MQ-4 analog interface int analogVal; //analog readings String message=""; void setup(){ // Initialize serial communication for debugging Serial.begin(9600); } void loop(){ // Read analog value from MQ-4 gas sensor analogVal = analogRead(analogPin); <span class="hljs-comment">// Check if gas concentration exceeds threshold</span> if (analogVal<=60) { Serial.println("Presence of gaz"); } else { Serial.println("Absence of gaz"); } delay(1000); } |

In this Program:

- The analog pin A0 is used to read the sensor's output.

- The threshold for gas concentration is set at 60 in this example. Adjust this value according to your requirements and the sensitivity of your sensor.

- The detected gas concentration is calculated assuming a linear relationship between gas concentration and voltage. This relationship may vary depending on the specific characteristics of your sensor, so it's crucial to consult its datasheet for accurate calibration.